ABS Plastic Sheet: A Versatile Material for Modern Applications

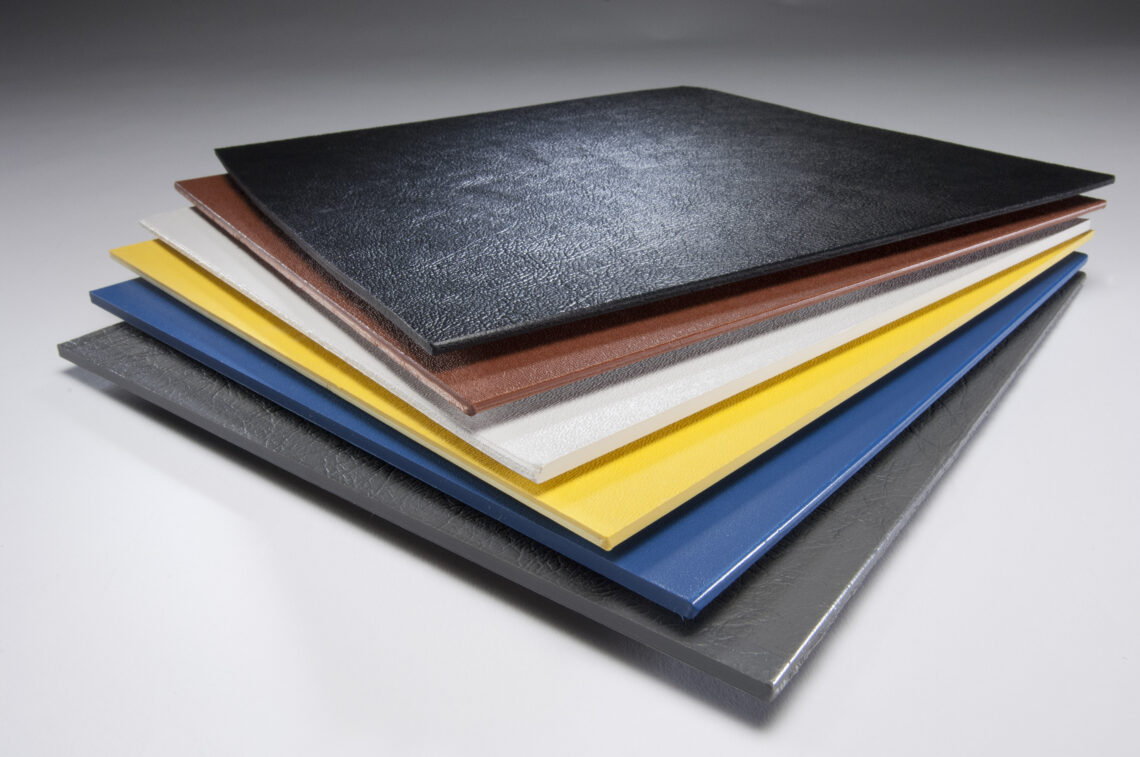

In today’s fast-paced world of design, manufacturing, and construction, materials that offer both durability and flexibility are highly sought after. Among these, the ABS plastic sheet has become a go-to solution across multiple industries. Known for its toughness, lightweight nature, and ease of fabrication, ABS plastic is not only practical but also cost-effective, making it a preferred choice for everything from automotive parts to consumer goods.

This article will dive deep into what makes ABS plastic sheets so valuable, their wide-ranging applications, benefits, and why businesses and individuals are increasingly turning to them for their projects.

What is an ABS Plastic Sheet?

ABS stands for Acrylonitrile Butadiene Styrene, a type of thermoplastic polymer. When processed into sheet form, it provides a smooth, rigid, and durable surface that can withstand impact and resist wear and tear. The combination of three monomers gives ABS unique properties:

Acrylonitrile provides chemical resistance and thermal stability.

Butadiene contributes toughness and impact resistance.

Styrene ensures rigidity and a glossy surface finish.

These characteristics make the ABS plastic sheet versatile and suitable for shaping, thermoforming, and machining.

Key Benefits of ABS Plastic Sheets

One of the biggest reasons behind the rising popularity of ABS plastic sheets is their outstanding balance of strength and usability. Here are some of their core benefits:

Durability and Strength

ABS plastic sheets are strong enough to withstand high impact, making them ideal for applications where durability is critical.

Lightweight Material

Despite their strength, they are lightweight, making them easy to handle, transport, and install.

Ease of Fabrication

They can be cut, drilled, machined, and thermoformed without losing their integrity, providing endless design possibilities.

Cost-Effective

Compared to metals or other plastics, ABS plastic sheets are affordable, making them a great option for bulk production.

Chemical and Scratch Resistance

They can resist everyday chemicals and abrasions, maintaining their polished look over time.

Common Applications of ABS Plastic Sheets

The ABS plastic sheet is widely used in industries because of its adaptability. Some of the most common applications include:

Automotive Industry

From dashboards to interior trims, ABS plastic sheets are widely used in car manufacturing due to their ability to withstand high-impact conditions.

Electronics and Appliances

The casing of many electronics, such as computers, printers, and vacuum cleaners, often uses ABS sheets for protection and aesthetics.

Construction and Architecture

Used in wall panels, protective covers, and decorative trims, these sheets enhance both function and design.

3D Printing and Prototyping

ABS plastic sheets serve as an excellent material for prototypes due to their machinability and strength.

Consumer Goods

Items like luggage, toys, and protective cases rely on the resilience of ABS plastic.

ABS Plastic Sheet vs. Other Materials

When compared to alternatives like acrylic or polycarbonate, ABS sheets often come out on top for projects that require impact resistance at a reasonable cost. Unlike acrylic, ABS doesn’t shatter easily, and while polycarbonate is stronger, it is also more expensive. This makes ABS plastic a balanced choice for most applications.

Why Businesses Choose ABS Plastic Sheets

For manufacturers and designers, the ABS plastic sheet offers flexibility, affordability, and efficiency. Its ability to be easily fabricated reduces production time, while its durability ensures long-lasting end products. Moreover, with sustainability becoming a global priority, ABS plastics can also be recycled, making them an environmentally conscious choice.

Conclusion

The ABS plastic sheet has proven itself as a versatile, durable, and cost-effective material across a wide range of industries. From automotive components to household products, its adaptability ensures it remains a staple in modern manufacturing and design. Businesses and DIY enthusiasts alike value its balance of strength, workability, and affordability, making it one of the most reliable plastic materials available today.

If you’re looking for a material that blends practicality with performance, ABS plastic sheets are an investment that delivers lasting value.

You May Also Like

4 Luxury Custom Mudroom Ideas for Your Home

September 27, 2021

Decorate your Garden with River Rock Landscaping

February 10, 2021